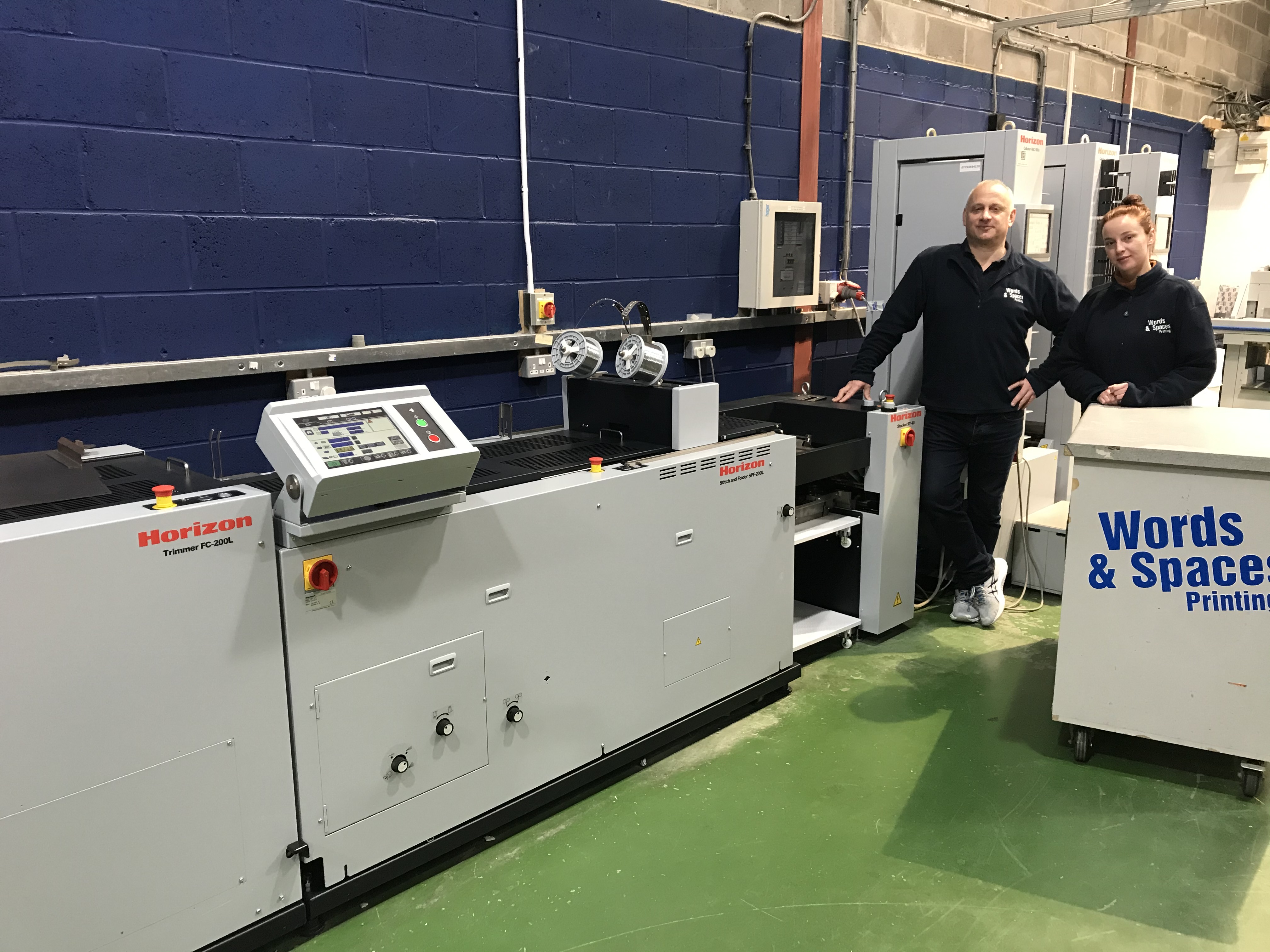

Isle of Man printer Words & Spaces has added landscape book production and streamlined operations with a Horizon SPF-200L bookletmaker from Intelligent Finishing Systems (IFS). It replaces a 10-year-old Horizon SPF/FC200A.

The operation that produces work for a wide range of customers including Santander, Friends Provident, Isle of Man Post and Isle of Man Government, has a unique problem when it comes to outsourcing work – a long wait for anything that is sent to mainland UK.

As a result, any investment made is done so based on today’s work demand with an eye on what tomorrow’s could be.

Mark Green, managing director, explains: “It was time to upgrade our bookletmaker and we wanted the ability to offer landscape book production in house. Before, when we were asked for the service, it made sense to get it printed and finished off the Island but we wanted to be able to manage that ourselves.”

The business runs a number of Horizon systems – a BQ270 perfect binder, a CRF-362 creaser/folder, and an AFC-566F folder. Mr Green continues: “We have always exaulted Horizon products. We did look at a leading competitor’s offering but we are pretty loyal to Horizon. We also liked the Horizon SPF-200L’s landscape capabilities. It is something we can now proactively promote as a service that can be completed fully inhouse and meet increasingly short turnaround times.

“We also chose a third tower collator, a Horizon VAC-1000, and a Horizon ST-40 stacker to help produce book blocks to feed the perfect binder. We can also now more easily handle grey boards for NCR jobs.”

The 4,500bph Horizon SPF-200L landscape feed bookletmaker combines stitching and folding with the ability to handle sheets up to 640mm in length. JDF-ready, it offers instant set-ups via a large icon-based colour touchscreen for user-friendly operation. The screen can be used for on-the-run fine tune adjustments as well as the storage and recall of up to 200 jobs.

Mr Green concludes: “We are looking forward to being able to proactively sell landscape booklet production as well as enjoy the streamlining and capacity improvements enabled by the collator and the stacker. The overall investment will expand our service offering and make us more efficient.”