Innovative print systems and solutions vendors will combine their expertise at the inaugural Think Smart Factory 2019. Created to stimulate future industry success by showcasing solutions that focus on fast, efficient and cost effective production, the event, will run from November 11 to 13, at Miyako Messe, Kyoto, Japan.

Think Smart Factory 2019 is sponsored by the TSF2019 consortium comprising of leading industry suppliers Horizon, Canon, Fujifilm, Konica Minolta, RMGT, goof, JSpirits Inc, Resologic, Ricoh, Screen and Value Machine International Co.

The concept was developed in response to the spread of the Internet of Things (IoT) which promotes networking wherever possible. The printing industry is no exception and the IoT is playing an increasingly important role in day-to-day business. As a result, it is looking to vendors not only to automate solutions for labour savings, but also to connect solutions through networks.

At IGAS 2018 leading companies gathered at Horizon’s Smart Factory Zone and participated in popular seminars examining this approach. This interest prompted the creation of Think Smart Factory 2019.

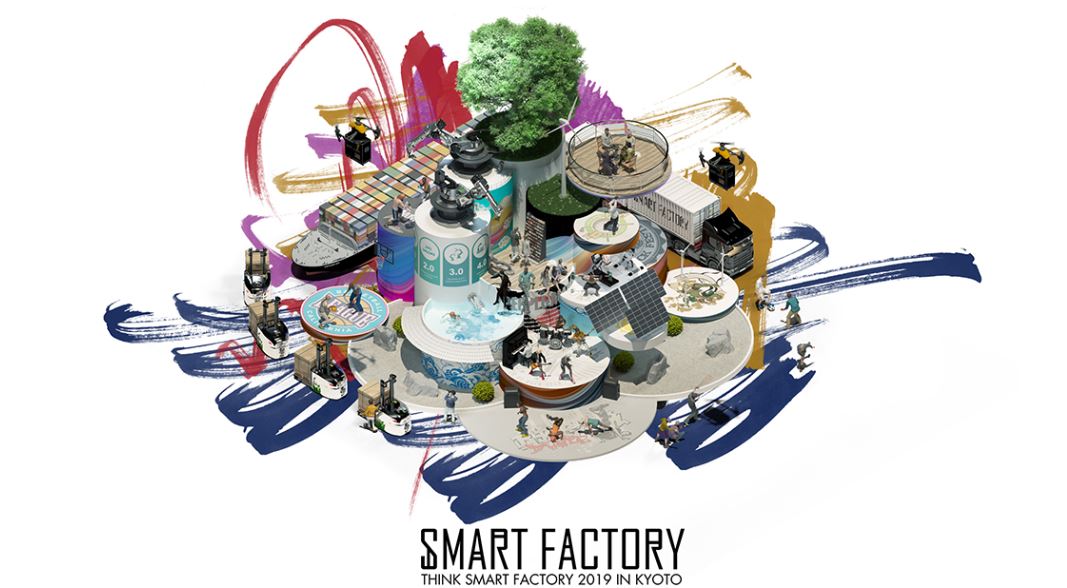

At Think Smart Factory 2019 every system in the hall will be connected via a digital workflow, an automatic transport system, and in-feeding and off-loading robots demonstrating a fully automated Smart Factory operation. Within the 4,000 sqm (43,000 sqft) of floor space, the end-to-end automated workflow will be demonstrated with a focus on finished products. In addition, digital technology will be the focus, demonstrating a high level of automation and quality through digital technology. Horizon’s solutions will be used for the finishing process and they will be connected from order entry to delivery.

One unique concept of the event is the elimination of individual vendor booths with the entire floor becoming a working environment to show real Smart Factory concepts in a live demonstration.

There will also be a Smart Factory Zone (theatre) presenting 16 sessions over the three days with English translation.

IFS supplies Horizon solutions in the UK and Ireland and Managing Director Bryan Godwyn comments: “The time and cost saving benefits of a smart, streamlined and smoothly operating bindery are well known but creating the optimum environment can be challenging. Any gains in a perfectly running post press set up can be lost if there are inefficiencies in print production. That is why showcasing the most efficient end to end operation in this way is so exciting. Visitors will be able to see the whole process completed in real time enabling them to visualise how their production processes can be enhanced.”

Further details about the show, including products, presenters and the workflow systems will be announced shortly.