Intelligent Finishing Systems has teamed up with Belgian firm Fit Things to offer cost effective, fast, and simple to produce, on demand packaging.

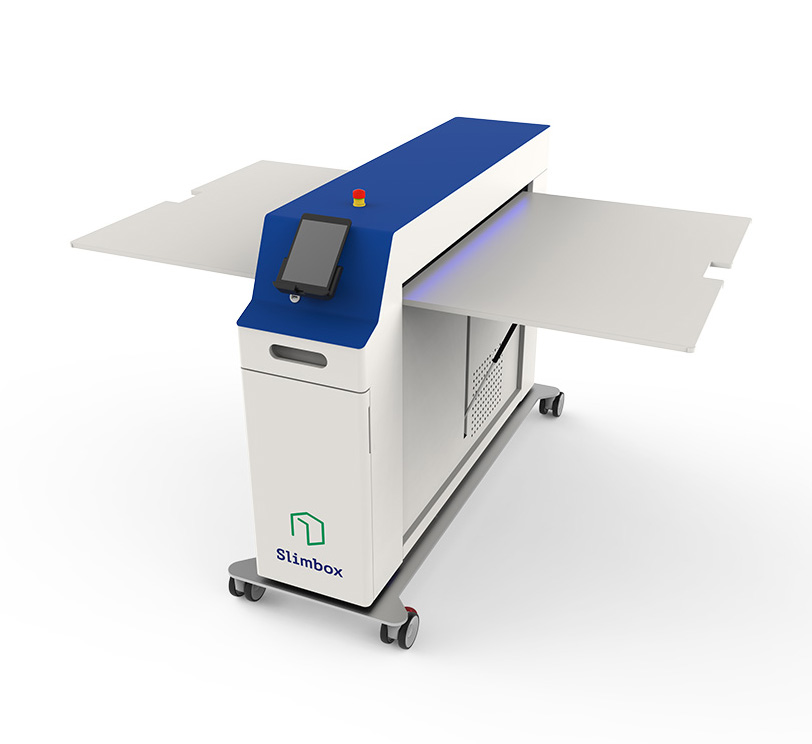

IFS will exclusively supply the Slimbox laser cutter to operations in the UK and Ireland. The compact and easy to run solution will be demonstrated by IFS for the first time at IPEX 2017, Birmingham NEC, October 31 to November 3, Hall 5 stand G450.

Says Bryan Godwyn: “With operations looking at ways to add differentiation Slimbox enables them to create branded, made to measure, packaging that reduces overpackaging and introduces a more environmentally considered on-demand approach.”

Slimbox is set up and operated via a PC or smart phone based app. A cardboard measuring tool helps set the dimensions of the product to be packaged. These are then entered via the app for the cutting shaped to be sized appropriately.

Cardboard sheets can be between 1mm and 5mm and up to 30 boxes per hour can be created – ideal for short to medium run packaging applications.

Continues Godwyn: “Its ease of use makes it a great addition to any operation. With no need for complex training it can be contributing to profitability from the moment it arrives.”

Fit Things Sales Director Tom Leys adds: “Our target group is smaller companies looking at manufacturing 20 to 150 boxes a day. We see potential in packaging for numerous uses from international air traffic shipping where packages are calculated on both weight and size to creative agencies looking to add value. There is also the ecological aspect to consider as smaller packages reduce waste and cut CO2 emissions.”

Fit Things will also be taking the Slimbox to Packaging Innovations September 13 and 14 at London Olympia stand F50.