New systems and solutions that open up exciting business models will be demonstrated for the first time in Europe at this year’s Horizon Finishing First 2022. The three-day event at the Horizon Academy, Quickborn, Germany, will run from September 27 to 29.

Taking place at the newly refurbished showroom, the future shaping technologies will highlight how greater automation and digitisation support new business approaches in finishing with robotics and software control via iCE LiNK.

Among the live presentations will be:

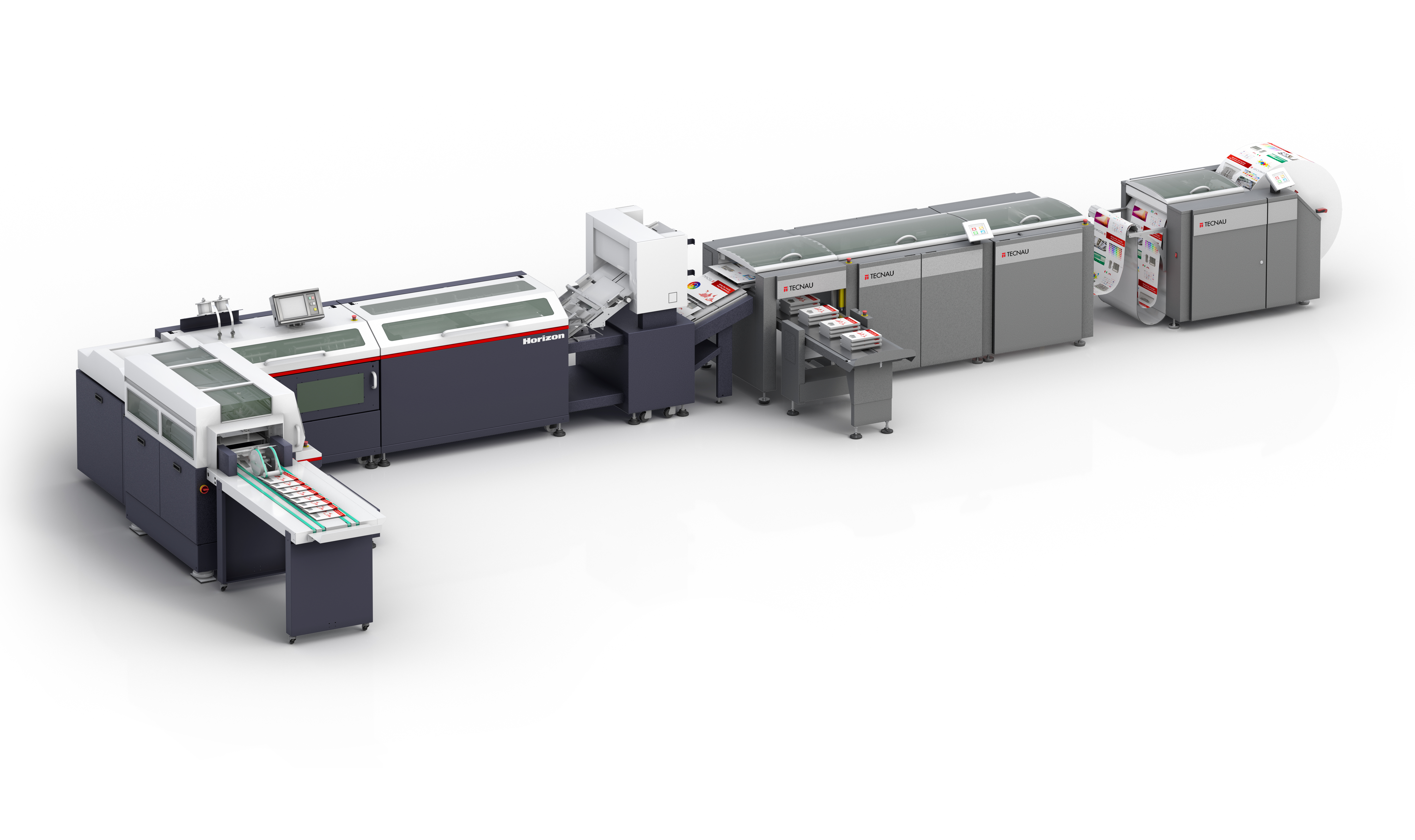

Horizon iCE StitchLiner Mark V

The next evolution of the successful StitchLiner saddlestitching family delivers increased productivity and flatter finished booklets with the development of the unique ACF-50D accumulator and folder overlapping transport mechanism.

Other features include:

- Expanded format size to meet A4 landscape and large format calendar production.

- Ability to manage a wider range of formats, including A4 landscape at over 5,000 booklets per hour.

- Consistent quality production with sheets tightly folded sheets and covers along the accurate scoring lines.

- Assured sheet-to-sheet integrity with inline configuration and optional barcode verification.

- Variable page booklet applications handled without any operator intervention.

- Flexible insertion of up to three sheets in the booklet with the optional CF-50D cover feeders, which can also be used as a digital sheet feeder.

Horizon iCE Binder BQ-500 with ESF-1000 end sheet tipping machine, LBF-500 loose sheet book block feeder and the GF-500 gauze feeder.

The case binding preparation system incorporates the new Horizon BQ-500 four clamp perfect binder that builds on the successful tried and trusted features of its BQ-470 and BQ-480 predecessors.

Enhanced functionality and improved operation are enabled by:

- Highly automated set up via a large 12.1 inch colour touchscreen.

- 21 automated sections from cycle and milling speed to roller height and guide positioning.

- Memory storage of up to 999 jobs.

- Pre-installed variable software capability.

- Variable thickness production of 5mm change at up to 800 books/hr

- New design features including a status light that indicates how the binder is running.

- Ergonomic design with all the operator required actions on the same side.

Horizon AFV-566FKT folding machine.

The new Horizon AFV-566FKT fully automated cross-folder is the evolution of the successful AFC-566FKT automated cross-folder. It answers an increasing need for binderies to be highly flexible and responsive with its ability to efficiently handle a wide variety of paper substrates and folding applications for high quality production.

Key features include:

- Up to 20% faster changeover thanks to a library of stored folds readily accessible on a new look 12.1 inch intuitive colour touch screen.

- A status checking screen for a quick at-a-glance overview.

- Auto Interval Function that adjusts to the optimum production speed automatically for higher productivity.

- Easy recovery at knife fold section to reduce downtime.

- Retainable Knife fold stoppers to minimise stoppages.

- Automated adjustment of hold-down roller on knife fold section to find the best position for smoother operation.

All three systems include Horizon’s cloud-based iCE LiNK IoT automation which uses cloud technology to automate workflow from upstream to post-press. It provides access to an intuitive easy to use dashboard that reports real-time production analysis for improved efficiency and profitability, remote update capabilities and scheduled maintenance resulting in less downtime. The information is accessible via smartphone, tablet or desktop PC and the software is designed for integration with many leading MIS systems.

Horizon RD-N4055DM rotary die cutter

Responding to the continued growth in labels, packaging and converting is the 6,000 cycles per hour Horizon RD-4055DMC Rotary Die Cutter with dual magnetic cylinder. It can produce high quality die-cutting up to 500 microns thick, crease, kiss-cut, emboss and perforate with high accuracy. A ‘Repeat Register’ function allows smaller flexible dies to be used for smaller products to help reduce the die cost. Image tracking automatically tracks the image area on digitally printed jobs to provide high quality registration to the printed image. Job changeovers and make readies are fast and simple.

Stand out features include:

- Five repeats in a single pass.

- Simple and easy operation cutting costly labour steps and increasing productivity.

- Maximum sheet size 400 x 550 mm.

- Substrate flexibility up to 0.5 mm.

- Optional waste stripping with no nicks.

- Optional Sheet and card Stackers.

Horizon Finishing First attendees will enjoy informative keynotes talks from industry experts and daily panel discussions moderated by INKISH TV’s Morten B. Reitoft. There will also be a company update from the Horizon team and exclusive networking opportunities with over 100 decision-makers per day from the German and European printing and media industry.

“This is a great opportunity to see the latest Horizon systems designed to help operations minimise production costs effectively while managing an increasingly broad range of products and run lengths,” says Eric Keane, IFS Managing Director. “The fully automated, easy to set up, simple to operate systems enable the delivery of high-quality results quickly. They allow operations to invest in future-proofed solutions that improve operational capabilities while opening up new possibilities.”