Horizon StitchLiner Helps Tristar Printers’ New Business Strategy Shine

Book production line puts print on demand at heart of Blackburn family firm’s added value focus

Like many printers, the recession has forced family-owned Tristar Printers, Blackburn, to re-think its business model. The outcome was a modernisation programme to re-position the operation as a value added service provider and the purchase of a Horizon StitchLiner 5500 fully automated saddlestitching line from Intelligent Finishing Systems.

Founded in 1982, the eight employee, £350,000 turnover operation has key relationships with local colleges and councils as well as regional and national businesses.

But the state of the economic climate has impacted the operation year on year leading director Abu Ahmed to undertake the broad review: “A lot of customers have gone bust, or reduced their printing needs, and runs have got shorter so we are not getting the same kind of volumes. There are also companies offering silly prices that we cannot see as being sustainable and don’t want to get involved with.”

That has prompted a re-focus of emphasis towards delivering value added services: “We needed to find ways to work smarter and not try to do what everyone else is doing. Before the recession we were working a lot with trade companies and design agencies. Now we are looking more into niche markets such prayer timetables as well as ways of developing our print on demand capabilities. We are looking at the possibility of adding web to print too. Importantly we want to focus on value added print so we can create better gross margins.”

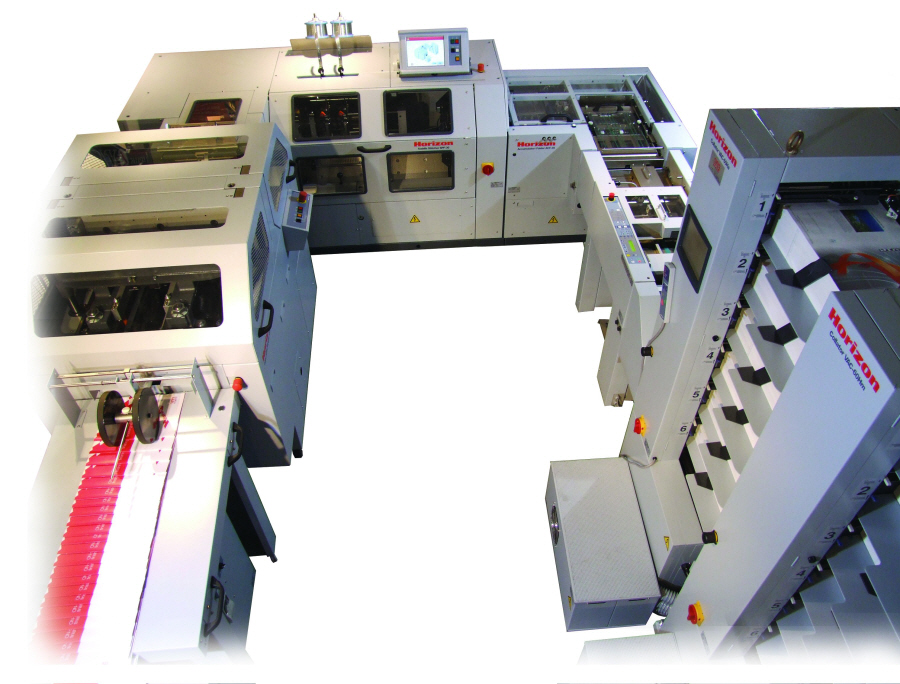

Central to this new strategic direction is a highly responsive bindery which is why the fully-automated 11,000bph Horizon StitchLiner, with two Horizon VAC-Turbo 60 six-station collators, was chosen to replace a Horizon SPF-FC20. Mr Ahmed was immediately confident of its overall performance and quality. “Apart for the easy of set up, fast makereadies and range of book sizes we like the flexibility of the bin sizes which means we can upgrade to the 10-bin collators as and when the demand increases,” he says.

There were others reasons the StitchLiner with its high profile icon-based colour touchscreen for set-ups in less than two minutes was chosen too: “We did look at a Duplo DBMi but we felt the StitchLiner was a much better build and more efficient. We can very easily marry covers and pre-collated digital blocks and that gives us more flexibility in terms of the jobs we can handle.”

As for the impact it has made to Tristar, Mr Ahmed says: “We have only had it a month but jobs have just flown through it. Runs that took days in the past are now done in hours. We can easily complete runs of one or runs of 5,000. We can also stop longer run work and complete shorter jobs before going back to the long run.”

He continues: “Now there is no need for us to outsource anything and that makes us faster, more productive and cuts costs.”

As for the future he adds: “We can now look at new markets. We can give the customer what they really want at a price point that is affordable. We have to go out more to find customers now and when we do we need to be sure our services are easily accessible.”

The key to the StitchLiner’s enduring popularity is its ability to work from flat four-page section, eliminating the need for separate bindery stages to be undertaken. Its integral three-knife trimming station means there is no need to pre-fold into signatures or pre-trim top and tail – resulting in significant time, waste and energy savings.