In Print invested in a Horizon StitchLiner 6000, supplied by Intelligent Finishing Systems, as part of its £500,000 investment programme to expand its production capabilities.

The Malton commercial printer is also preparing to move into neighbouring premises adding 4,000 square feet to its existing 9,000 square feet.

Explains Paul Coulson, who founded the family run firm in 1983: “The industry has changed and we are handling smaller run jobs with faster turnaround times. My son Lee is preparing to take over and we wanted to streamline production to make it a smoother, faster, process.

“We have to get the work in, on the press and completed and out the door as fast as possible. It is no good spending money on presses and then not having the right equipment to finish it. Moving into the premises next door and investing in new finishing capabilities will allow us to create a more productive environment.”

Mr Coulson chose the StitchLiner 6000 after viewing it at drupa but also following experience of the Horizon solution. He says: “This our third StitchLiner. They have been extremely good machines. We looked at the StitchLiner 6000 at drupa. It had everything on it that we needed. It was a dedicated bookletmaker. We couldn’t have anything else.

“We liked the different direction of the feeder and the fact that the booklet is produced in a straight line. One of the first runs was 45,000 books. We have lots of jobs like that and the StitchLiner is ideal. You can just set it up and let it run.”

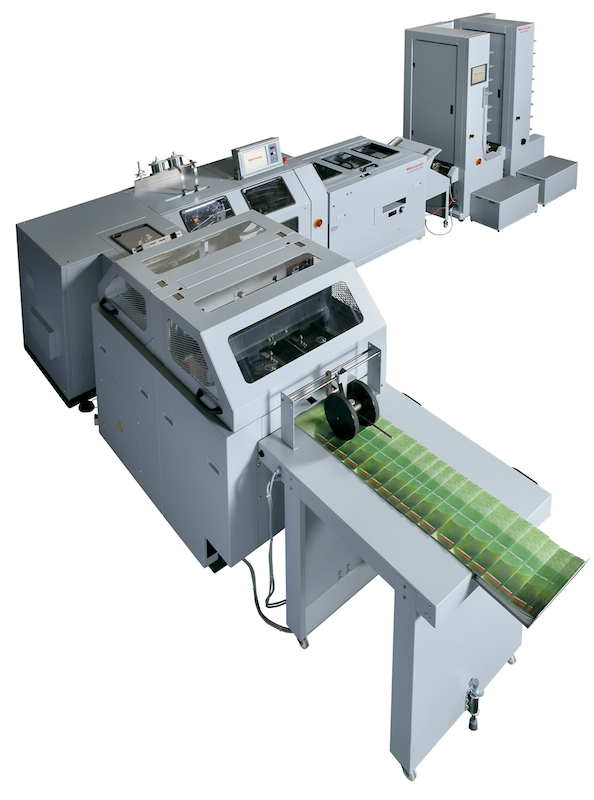

The StitchLiner 6000 takes a flat sheet, then folds, stitches and trims in one complete process eliminating the time and cost of pre-folding signature sections or pre-trimming. Its user-friendly set up through a colour touchscreen and high level of automation allows short make-readies for quick turnaround. Make readies can be completed in minutes and job memory storage enables the specifications of repeat work to be easily recalled.

It can incorporate a centre knife in the three-knife trimmer to double running speed to 12,000 bph in two-up production. Its new landscape feeding and straight saddle-stitching flow enables the smooth production of thinner paper stock and larger, landscape-oriented sheets.

As for return on investment Coulson says: “This is something we needed. We took a long-term view that to complete finishing in the most efficient way the StitchLiner 6000 was the best system.”

The StitchLiner was installed at the end of last month (November) and it has already been put through its paces states Coulson: “Since it has gone in we have run lots of our regular work on it and it has been very reliable. It is a superb addition.”