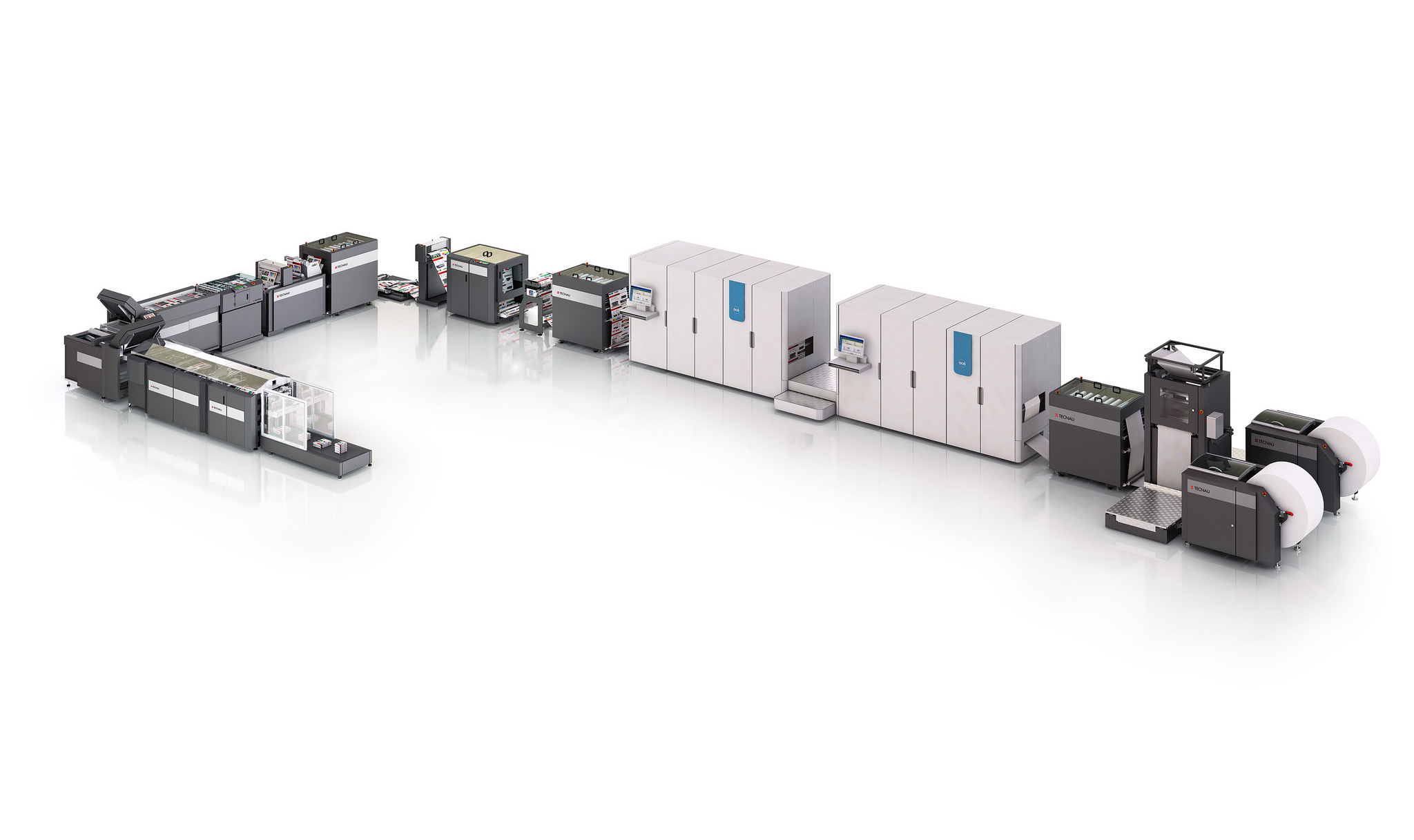

Building on its deep foundation in providing leading-edge, reliable solutions to transactional and direct-mail customers, Tecnau, partnered in the UK by Intelligent Finishing Systems, will continue its increasing focus on the books and graphic arts marketplaces during drupa, Dusseldorf, Germany, 31 May – 10 June.

Highlighted on the Tecnau stand (Hall 8a, stand D63) is Libra One, providing book block assembly behind the new Canon Ocè ColorStream 6000 Chroma. Libra One is a fully integrated and automated system, allowing variability from one book to the next in height, width, thickness and imposition. With Libra One’s ability to produce “books-of-one”, users can slash book stocks to zero, reducing dramatically paper waste and the risk of unsold inventory. The system enables users to reach new markets where short runs are mandatory, such as manuals, limited editions, and new authors publishing.

Tecnau also announces the general availability of the new Libra One CS, a Libra One model supporting sheet-fed operations. Libra One CS eliminates the manual guillotine process and automatically transforms single sheets up to 13” x 19” in size into pre-glued book blocks ready for inline or nearline binding. The unit automatically changes from 2-up to 4-up imposition and back with no make-ready time, at a constant speed up to 16,000 sheets per hour, even when running book of one production.

Other solutions on show will be the new Stacker s25 in conjunction with the established Cutter c23. The Stacker s25 features a new gripper technology to provide reliable, damage-free handling of heavy-ink-coverage graphic arts applications. Cutter c23 has dual rotary knives to sheet the web using single cut or variable double strip cut for full bleed colour printing or removal of inkjet flush lines. On the Cutter c23/Stacker s25 will be Tecnau’s WebVision quality monitoring system. WebVision guarantees print quality, and goes beyond to offer significant data integrity and workflow testing capabilities.

There will be the new TC 7000 W cutter too. It supports web widths of up to 560mm (22”). The guillotine cutter can handle a wide range of media, from 50gsm up to 250gsm. As with all products in Tecnau’s TC 7000 series, it can be combined with multiple output solutions, including an offset stacker, a shingling conveyor and various third party finishing devices

An expanded version of Tecnau Connect (formerly known as PrePost Manager) will be demonstrated. The central platform to control the most complex Tecnau finishing lines, collect data and generate reports, enables remote technical support and performs essential integrity controls.

Tecnau will announce the availability of two solutions for long sheet cutting and stacking, the new Stacker s28 and High Pile Stacker h10. The Stacker s28 is based on the well-established Stacker s20 and is designed to collect up to 250mm-tall offset stacks of sheets, up to 28” long (710mm), with automatic job separation, in order to support the increasing demand for short run commercial print applications such as calendars, posters and banners. The High Pile Stacker h10 is aimed at higher-volume users, as it collects high piles up to 700mm-tall on a pallet for easy transport to further finishing. The Stacker h10 offers continuous delivery (with no pause for stack removal), supporting continuous print operations, and an optional cardboard feeder for job separation.

Finally, Tecnau will introduce NewsReady, an entry level solution for digitally-printed newspaper production. The modular design offers a high degree of flexibility for users, allowing the system to be configured for short run newspaper production and then changed over to 1up and 2up offset stack output such as books and commercial print applications. The reconfiguration is quick and simple and can be performed multiple times per day in order to maximize the utilization of continuous feed digital printers.

Comments Giuliano De Marco, Tecnau CEO, “Tecnau is excited to show leading-edge finishing solutions for books and commercial print at drupa 2016. Our drupa exhibition signals our commitment to provide users with solutions that allow them to fully exploit the opportunities presented by today’s high-speed inkjet printing engines.”

Tecnau also will be exhibiting both new and established solutions with a broad variety of digital printing and finishing partners:

- Ricoh (Hall 8a B46)– Tecnau will unveil its new Roll 9 system in twin showings. At Ricoh, Roll 9’s Unwinder u9 will feed roll paper to the Ricoh Pro VC60000 continuous feed inkjet printer, with the Rewinder r9 forming rolls on the back end. Featuring adjustable web tension control, Roll 9 accommodates the wide range of tensions required for varying paper specifications to be run by varying high-speed colour inkjet printers.

- Screen (Hall 8a C11) – Roll 9 will provide feeding and finishing for the Screen Truepress Jet520 HD.

- Canon (Hall 8a B50) – Completing the exhibition of Libra One on Tecnau’s own stand, Tecnau’s Zero Speed Splicer u40 will provide roll feeding for Canon’s new high-speed digital printing system, Ocè ColorStream 6000, in the neighbouring Canon stand; the printer in turn supplies printed output in-line to Libra One. The Zero Speed Splicer u40 allows roll changes with virtually no printer downtime, maximizing printer productivity and eliminating paper waste associated with printer stoppages due to roll depletion. Thanks to the smart interface developed by both companies, the Splicer u40 allows on-the-fly media variation including automatic loading of print parameters in order to support true book of one production with variations in 4 dimensions: height, width, length and paper type.

- Elsewhere on the Canon stand, Tecnau will introduce the new TC 1530 C2 cut-sheet dynamic perforator. The TC 1530 C2 is integrated with Canon’s recently introduced Océ VarioPrint i300 colour sheet-fed digital press, will provide in-line dynamic perforating to a sheet-fed digital press in an industry first. Coupons, convenience checks, remittance stubs are just a few of the broad range of applications users may create page-by-page within a single print run.

- Xerox (Hall 8b A 62) – Tecnau is proud to exhibit its high-speed Roll 20 roll-to-roll solution along with the Stack 2020 cut/stack system on the just-announced Trivor 2400 Inkjet Press. Supporting speeds up to 254 meters per minute, the Unwinder u20 features a new airshaft design for smooth feeding of a paper roll up to 22.5” wide and 52” in diameter into the digital press. The Unwinder u20 offers automatic detection for roll feed direction and semi-automatic roll loading. The Rewinder r20 has an automated loop control for quick and easy loading of the paper web, as well as an automatic tension control system for an easy switch between applications of varying paper weights.

- Also on the Trivor 2400 Inkjet Press, Stack 2020 provides sheeted output, with the focus at drupa on a variety of book applications.

- Finally on the Xerox stand, Tecnau will exhibit its SheetFeeder NV roll feed system for the Xerox Nuvera 314 sheet-fed digital printer. SheetFeeder NV sits next to the input side of the printer and includes a quick-change unwinder and precision cutter. By feeding as many as 60,000 sheets from a single 50” diameter roll, users print more in less time while lowering paper and labour costs.

- HP (Hall 17 A01) – Tecnau will show its CutReady cut/stack solution finishing output behind the HP Indigo w6800. CutReady supports a broad array of applications, media types, and paper weights – completing one up, two up, and three up output in standard photo sizes. It delivers lay-flats for offline finishing, book covers with inline or offline lamination, calendars, canvas and other specialty products, as well as long- sheet applications such as posters and banners, while ensuring high accuracy cross-cutting and side-trimming for full bleed applications.

- Horizon (Hall 6 D05) – Tecnau will display the Stack 2020 cut/stack system inline to the Horizon book finishing solution, including the BQ-470 binder and HT-1000 three knife trimmer, in a pair of partner locations at drupa. The Stack 2020 is configured with an Unwinder 550, Cutter c20, Stacker s20 and Transport Table 568 to support a dual output delivery: the Stacker s20 can be bypassed to send single sheets to the Horizon system or alternatively can be used to cut and stack book blocks, with 90 degree delivery and offline finishing. The Roll to finish line is suitable for medium to short run production.

- FujiFilm Hall (8b A25) –Tecnau’s Stack 2020 will again deliver sheets to the Horizon book finishing solution, this time in a nearline configuration to FujiFilm’s Jet Press 540w.

- Böwe Systec (Hall 6 B39) – Tecnau presents in Hall 6, stand B39 the Unwinder u10 inline to Böwe Systec Fusion Cross, high speed inserting system, supporting a broad variety of envelop formats and media variation, for the transaction and direct mail markets.

“Tecnau highly values these opportunities to exhibit the fruits of our close relationships with our many partners both in the digital printing and finishing marketplaces. We’ve placed a number of new product offerings in partner stands at drupa, so we encourage our customers and prospects to visit partners as well as Tecnau’s own stand to see the latest in the world of feeding and finishing innovations for digital print,” says De Marco.